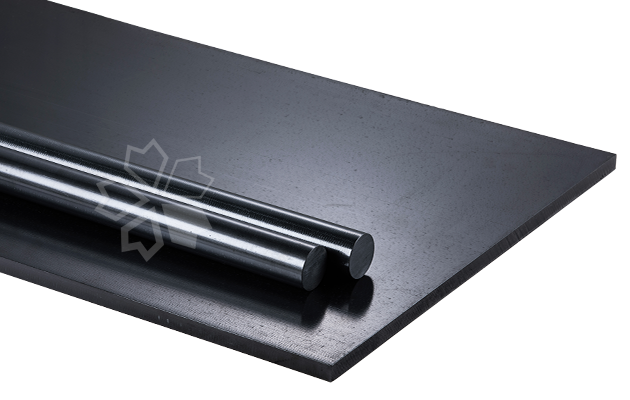

PPS - VIRGIN RESIN

Polyphenylene sulfide is a thermoplastic engineering plastic containing a phenyl ring with a sulfide bond in the main

chain of the molecule. The rigid structure of the phenyl ring is connected by flexible sulfide bonds, which makes it have

excellent heat resistance, flame retardancy, chemical resistance, and good affinity with inorganic fillers.

in the main

chain of the molecule. The rigid structure of the phenyl ring is connected by flexible sulfide bonds, which makes it have

excellent heat resistance, flame retardancy, chemical resistance, and good affinity with inorganic fillers.

Zero Engineering invented the "Pulse Extrusion" (Invention Patent No. 201410330331.1) in 2014, and it has been successfully used in mass production of PPS sheets and rods. The current product has upgraded to the fourth generation. The fourth-generation products use custom-developed special extrusion raw materials to control the black spots; we process the surface by cross-linking, which improves the comprehensive mechanical performances. The products are suitable for the precision electronics industry. The trademark of this series is ZEFIRST®.

in the main

chain of the molecule. The rigid structure of the phenyl ring is connected by flexible sulfide bonds, which makes it have

excellent heat resistance, flame retardancy, chemical resistance, and good affinity with inorganic fillers.

in the main

chain of the molecule. The rigid structure of the phenyl ring is connected by flexible sulfide bonds, which makes it have

excellent heat resistance, flame retardancy, chemical resistance, and good affinity with inorganic fillers.

Zero Engineering invented the "Pulse Extrusion" (Invention Patent No. 201410330331.1) in 2014, and it has been successfully used in mass production of PPS sheets and rods. The current product has upgraded to the fourth generation. The fourth-generation products use custom-developed special extrusion raw materials to control the black spots; we process the surface by cross-linking, which improves the comprehensive mechanical performances. The products are suitable for the precision electronics industry. The trademark of this series is ZEFIRST®.

DETAILS

PERFORMANCE

- Maximum operation temperature can reach 210℃ (Notice: the actual mechanical performance drops to half of the normal temperature at 120℃)

- Maintain high mechanical strength, stiffness, and hardness in high-temperature environments

- Excellent chemical resistance, insoluble in all organic solvents below 200℃

- Good radiation resistance

- The molecular structure contains sulfur atoms, which is inherently flame-retardant (UL94V-0)

- Low dielectric constant and less dielectric loss, which can be a good material for 5G

APPLICATIONS

- When it couldn’t be met in the requirements of using PA, POM, PET, etc., while it will increase the cost if you use the PEEK, PI, and PAI, in that case, PPS is the best choice;

- 3C electronic equipment components;

- Inspection fixtures;

ATTENTIONS

- The ultraviolet light and fluorescent light may affect the appearance of the materials, causing it turns to dark brown;

- It is highly recommended to use both fiberglass and carbon fiber to ensure the airtightness of the material.

SPECIFICATIONS (mm, g/cm³)