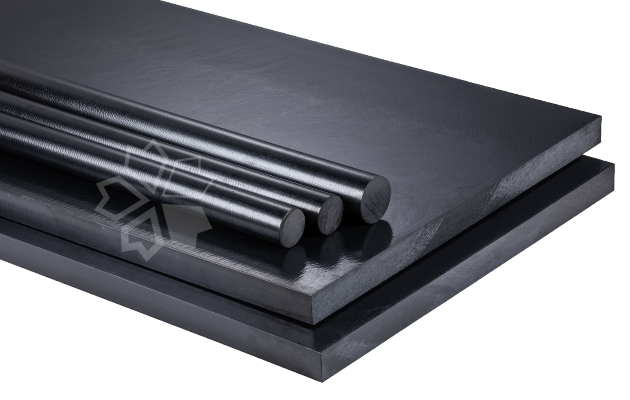

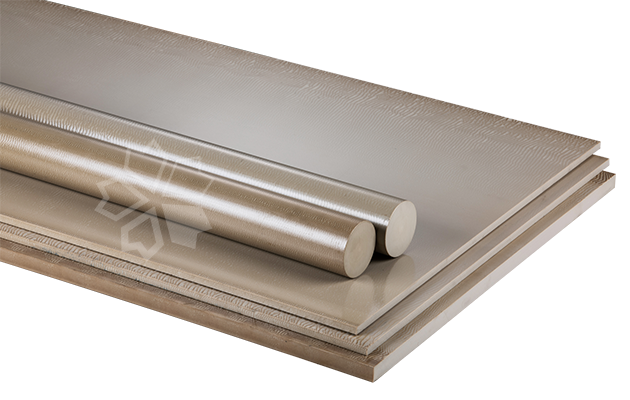

PEEK - 30% GLASS FIBER

Compared to pure PEEK, GF30 shows better rigidity and creep resistance as well as dimensional stability. As the glass fiber

would be easier to scratch the matching surface when choosing this material as a sliding part, we suggest checking its

suitability carefully. It can bear the fixed load at a high temperature for a long period.

DETAILS

FEATURES

- Using GF30-PEEK may easily reveal the fibers during extruding products, but Zero Engineering could perfectly deal with this problem with its trick technology called fiber-compressed.

- Glass fiber easily agglomerates and unevenly disperses in the final product, causing anisotropy. Zero Engineering could overcome this difficulty with its "dynamic-distribution technology," achieving the isotropy of each part in the products as well as even fiber dispersion. (It is significant to have this technology because the unevenly dispersed of internal fiber in the final product would most cause a great difference between the final product and raw material)

ATTENTIONS

- Reinforced glass fiber materials tend to crack due to their low tensile elongation, which means the larger scale the product has, the higher cracking risk it gets. Therefore, we highly suggest being careful during cutting.

- Please heat the material to 80°C by a hot air circulating airbox before machining, or soak it in hot water remained 80°C for 3 to 4 hours;

- It is significant to use a fine cutting tool during cutting and drilling. If it is for an ultra-precise part, please process it into a rough sample, then anneal it again before finishing it.

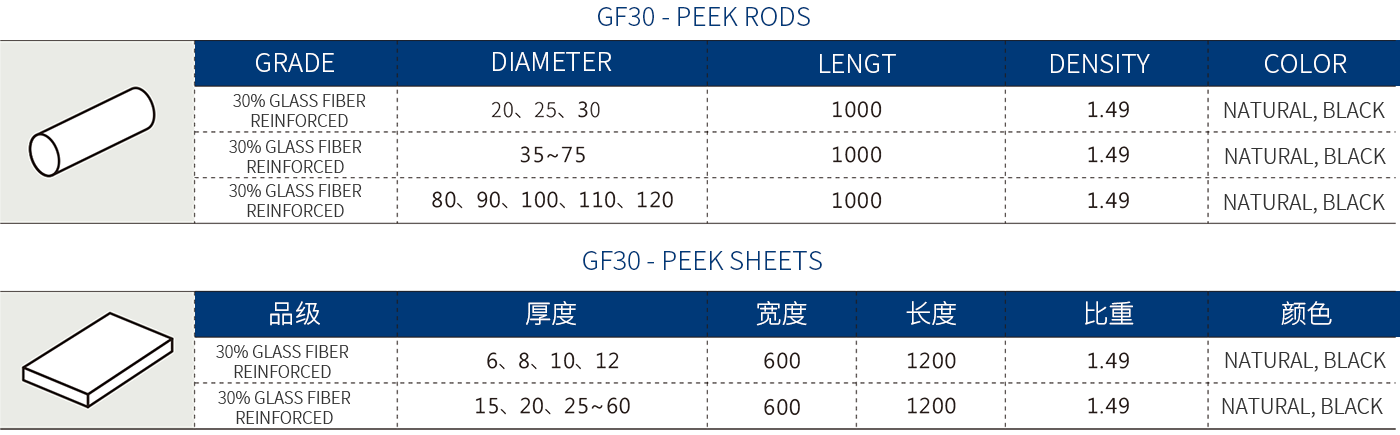

SPECIFICATIONS (mm, g/cm³)